What do you do when you want to drink a cup of tea? You want to have a mug that is light, sturdy, waterproof, not burning hot to touch, and something you can easily rinse off when you are done. It sounds easy, but over time countless artisans have tried to come up with just such a material. Chinese Porcelain has remained an important industry and secret of the Middle Empire. It has been constantly renewed at home and exported extensively abroad, from Southeast Asia to the east coast of Africa the since its early days.

Making Chinese Porcelain

Porcelain is a special category of ceramics. It has a binary composition made of kaolin clay and porcelain stone. Kaolin clay takes its name from the village Gaoling, close to the city of Jingdezhen in today’s Jiangxi Province, located in southeastern China. Kaolin clay is very fine and stable mineral rock rich in silica and aluminum. It can be found in several locations in the world including Vietnam, Iran and the United States, but its fame is tied to Jingdezhen and its longstanding imperial kilns. Porcelain stone, also called petuntse, is a type of dense, white mineral rock rich in mica and aluminum. A combination of these two ingredients gives porcelain its trademark impermeability and durability. The grade and price of the porcelain vary according the ratio of kaolin clay to petuntse.

Jingdezhen Porcelain Workshops

Jingdezhen is a town entirely devoted to its imperial kilns. Each artisan is trained to perfect one of the seventy-two procedures required to make one piece of good chinaware. It ranges from shaping the vessel on a hand-powered potter’s wheel, scraping a dried unfired vessel to attain desired thickness to painting the perfect single blue cobalt line on the rim. One should never overstep.

Most importantly, what marks porcelain’s difference from other types of ceramics is its high firing temperature. True porcelain is high fired, meaning that a piece is usually fired in a kiln at around 1200/1300 degrees Celsius (2200/2300 degrees Fahrenheit). The kiln master is the highest paid of all craftsmen and can tell the temperature of the kiln, often burning continuously for a dozen hours, from the color of a drop of water instantly vaporizing in the heat. After all, if he fails, one can expect a fully packed kiln of useless cracked pieces.

Even though there are no defined date as to when the first porcelain piece was made, porcelain became a prevalent type of ware used by the Chinese from the 8th century and on, during the Tang dynasty (618 – 907 AD). Many different types of porcelain ware flourished throughout the successive dynasties and became imitated internationally.

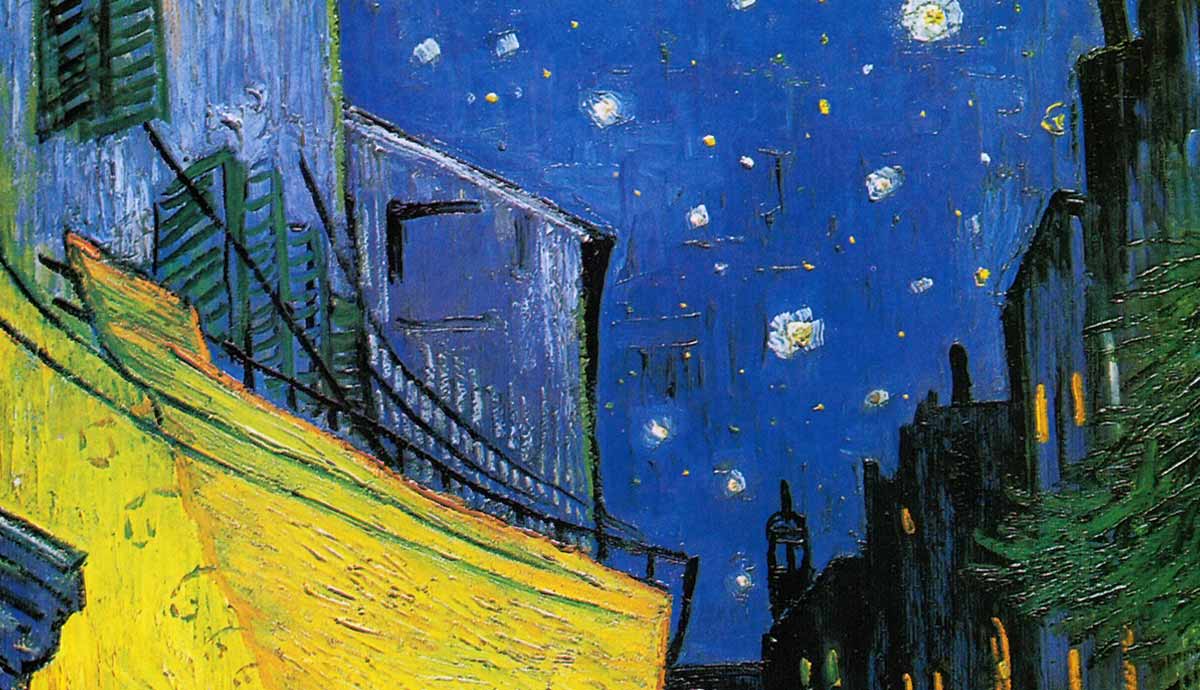

Blue and White

Blue and white decorated vessels are the image appearing in one’s mind when you think about Chinese porcelain. However, blue and white porcelain works are quite the newcomer to the family. As an artistically distinctive category, they only came about in maturity during the Yuan dynasty (1271-1368 AD), which is definitely a later period by Chinese historical standards. The David Vases now housed in the British Museum in London are the ones with the earliest date recorded on the vessels. Decorated with patterns of elephants, vegetation, and mythical beasts, they were made in the year 1351 AD, the 11th year of the Zhizheng reign, as votive offerings to a Taoist temple by Mr. Zhang.

The quintessential decorations on a piece of blue and white porcelain are the motifs painted in blue under a layer of transparent glaze. This color comes from the element cobalt. It is first imported to China from faraway Persia, adding to the preciousness of early blue and white porcelain pieces. Gradually, Chinese cobalt mined from different areas of the empire became used. Depending on the blueness of the motifs, veering purple for the Persian stock and a smooth sky blue from that mined from Zhejiang, popular during the early Qing dynasty (1688 – 1911 AD), an expert can often tell by the fired color of cobalt when the piece was made. Blue and white porcelain works are extremely popular both at home and for export. They exist in all styles and shapes from the tiniest rouge pot to enormous dragon vases.

Chinese Porcelain Marks

Of course, not everyone can date a piece of Chinese porcelain by a peak of the cobalt’s tone. That’s when reign marks come in handy. Reign marks are usually found on the bottom of imperial made porcelain pieces, bearing the reign name of the emperor ruling when it was made. It became standard practice from the Ming Dynasty (1369-1644 AD) onwards.

Most often, it exists in the format of a six-character underglaze cobalt blue mark in regular or in seal script, sometimes enclosed by a double-ring of blue lines. The six characters, from right to left and from top to bottom according to the Chinese writing system, refer to the dynasty in two characters and the reign name of the emperor in two characters followed by the mentioned “made during the years of”. This tradition continued until the short-lived monarchy of the China’s very last self-styled Hongxian Emperor (reigned 1915-1916 AD).

Reign marks can also be found on other types of vessels, such as Ming Dynasty bronzes, but far less consistently than on porcelain. Some marks are apocryphal, meaning that later productions were given an earlier mark. This was sometimes done as a tribute to an earlier style or to increase its mercantile value.

Emperors’ reign marks are not the only ones that exist. Sometimes craftsmen or a workshop would also sign their works by using a special icon, such a leaf. It is inherited today by producers of porcelain to stamp or mark their products with company names and/or places of production on the bottom of cups or bowls that you may find in your cupboard.

Monochrome

Monochrome porcelain refers to vessels glazed with one single color. It has been a historically diverse and popular category throughout Chinese history. Some even acquired their own name, often associated with the location where they were produced, such as green celadon ware from Longquan or immaculate Dehua white porcelain. From the early black and white wares, monochrome vessels developed every possible color one can imagine. During the Song Dynasty (960-1271 AD), the five greatest kilns competed against each other to produce the most exquisite pieces. These ranged from Ru kiln’s delicate bird egg like blue glaze to Ding ware’s elegance outlined by a cream tinted glaze over carved design.

The range of colors became infinitely varied as porcelain glaze types developed. During the Qing Dynasty, monochrome vessels included colors from very deep burgundy red to fresh grassy green. Most of them even had very poetic names. A certain shade of green veering on burnt brown is called “tea dust” whereas a demure deep pink is called “peach skin”. Different metallic chemic elements added to the glaze, undergoing reduction or oxidation in the kiln, are responsible for this spectacle of colors.

Famille-Rose Chinese Porcelain Vases

Famille rose porcelain is a popular later development that became perfected in the 18th century. It is the result of combining two different techniques. By then, Chinese potters had mastered the skills of making porcelain and glaze. Western enamel colors also became popular at court.

Famille rose pieces are fired twice, first at a higher temperature – around 1200 degrees Celsius (2200 degrees Fahrenheit) – to gain a stable shape and smooth glazed surface on which patterns drawn with various bright and bold enamel colors are added, and a second time at a lower temperature, around 700/800 degrees Celsius (about 1300/1400 degrees Fahrenheit), to fix the enamel additions. The final result boasts more colorful and detailed motifs standing out in slight relief. This lavish courtly style is very different from the monochrome pieces and incidentally coincidences with the rise of the Rococo style in Europe. It shows one of the many possibilities experimented with Chinese porcelain.

Chinese porcelain remains a much loved, collected and innovated category. The types discussed here demonstrate its longevity and diversity but in no way exhaust the styles and functions explored by potters in the last ten centuries of its history.